Укажите рекомендуемую цену:

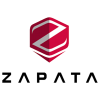

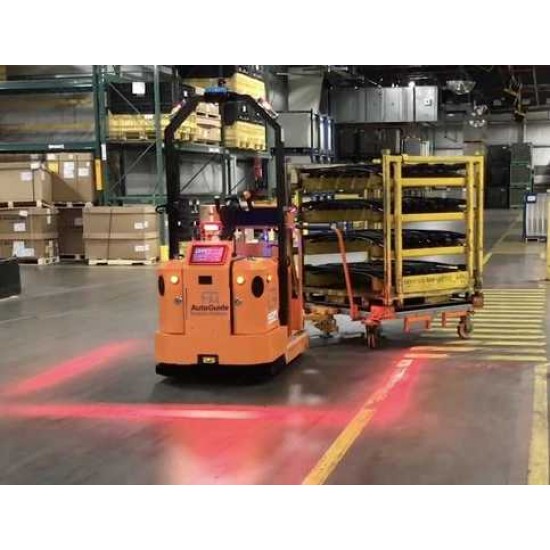

С помощью AutoGuide MAX-N Base AMR вы можете перенастроить и переназначить один AMR в соответствии с постоянно меняющимися потребностями

вашего производственного помещения. Множество адаптеров с высокой полезной нагрузкой включает буксировщики, штабелеры для поддонов, домкраты для поддонов и высокие отсеки.

РАЗРАБОТКА МОБИЛЬНОГО РОБОТА

Создан по индивидуальному заказу, чтобы стать полностью автономным мобильным роботом, а не ручным устройством, модифицированным для автономной работы.

Прочная конструкция для промышленных условий.

Высокая грузоподъемность, позволяющая перевозить большие грузы за одну поездку.

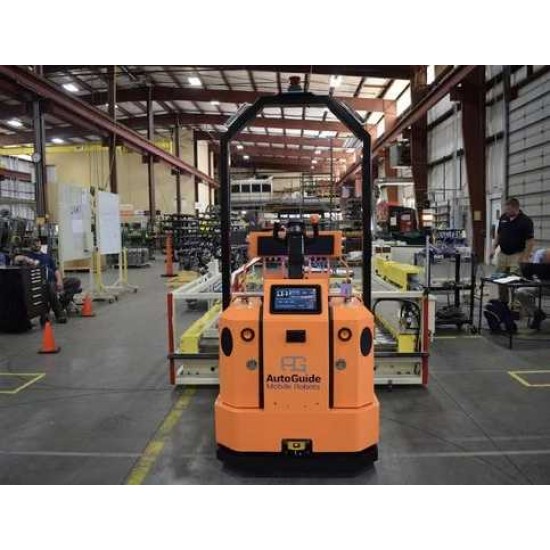

РАЗРАБОТАН ДЛЯ ОБЩЕГО РАБОЧЕГО ПРОСТРАНСТВА

БЕЗОПАСНО РАБОТАЕТ ВМЕСТЕ С СОТРУДНИКАМИ

Технологии LiDAR и SLAM с высоким разрешением позволяют отображать объекты в реальном времени и обнаруживать препятствия даже в условиях низкой освещенности.

Бесконтактное предотвращение столкновений при движении вперед и назад.

Соответствует и превосходит стандарты безопасности ANSI и CE для промышленных транспортных средств без водителя .

Сотрудники могут чувствовать себя в безопасности благодаря предсказуемым движениям AMR AutoGuide, которые проезжают через ваш объект по предполагаемым маршрутам, разработанным вами.

НЕ ТРЕБУЕТСЯ СЛОЖНОЙ ИНФРАСТРУКТУРЫ

Встроенные датчики всестороннего обнаружения. На вашем предприятии не требуется устанавливать напольную ленту, метки RFID, зеркала или отражатели.

AMR и программное обеспечение для управления парком работают на вашем существующем локальном сервере и в сети Wi-Fi.

Лучшее в отрасли время выполнения заказа, потому что устройства AutoGuide AMR производятся в США с готовыми компонентами.

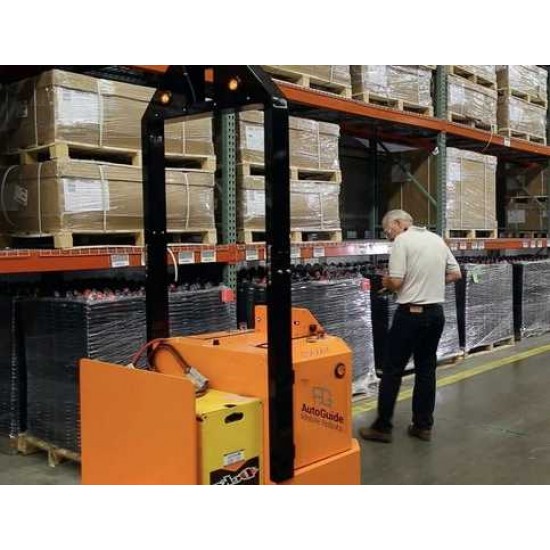

СОЗДАН ДЛЯ ЭКОНОМИИ ВРЕМЕНИ

ОПТИМИЗИРУЕТ ЕЖЕДНЕВНЫЕ ОПЕРАЦИИ

Программное обеспечение для управления автопарком SurePath направляет AMR в режиме реального времени, чтобы избежать пробок и оптимизировать маршруты движения.

Подключается к существующей системе управления заказами, поэтому процессы выполнения начинаются сразу после получения заказов.

Функции искусственного интеллекта позволяют роботам MAX-N наблюдать и учиться, помогая все больше и больше в сложных операциях разгрузки и погрузки.

РАБОТАЕТ БЫСТРО

Измените конфигурацию единой базовой AMR для выполнения нескольких задач и увеличения времени безотказной работы.

Всегда ездит по наиболее эффективным маршрутам.

Лучшая в отрасли скорость до 4 миль в час при полной нагрузке.

Возможность автоматической зарядки обеспечивает максимальную доступность.

Встроенный сенсорный экран позволяет сотрудникам переключаться в режим «Человек на борту» и сразу же выполнять ручную работу.

- Запас: Pre-Order

- Модель: MAX-N Base