Укажите рекомендуемую цену:

Vortex Bladeless - это альтернативный и инновационный способ использования энергии ветра с различными захватывающими характеристиками, что делает его революционным в производстве энергии ветра.

ЧИСТАЯ ЭНЕРГИЯ С VORTEX

В технологии Vortex не используются лопасти, а энергия ветра получается за счет колебаний без использования шестерен, тормозов и масла. Его дизайн делает его хорошей альтернативой для более экологичного поколения.

- Низкие расходы

- Безвреден для дикой природы

- Шестерни и тормоза

- Нуждается в смазке

- Автономный и автономный

- Легкие, минимальные затраты на сырье

- Быстрая реакция на смену ветра

Vortex Bladeless - это резонансный ветрогенератор, вызывающий вихревую вибрацию. Он использует энергию ветра из явления завихренности, называемого вихревым выпадением. В основном безлопастная технология представляет собой цилиндр, закрепленный вертикально с помощью упругого стержня. Цилиндр колеблется в диапазоне ветра, который затем генерирует электричество через систему генератора переменного тока. Другими словами, это ветряная турбина, которая на самом деле не является турбиной.

Ветряные генераторы Vortex больше похожи по характеристикам и рентабельности на солнечные батареи, чем на обычные ветряные турбины.

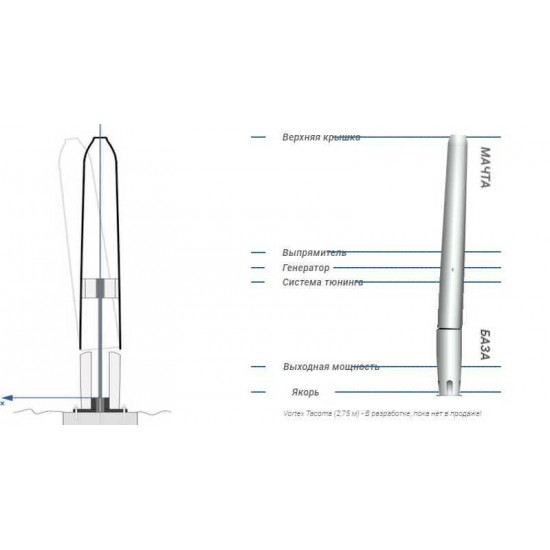

СТРУКТУРА И ГЕОМЕТРИЯ

Внешний цилиндр имеет большую жесткость и способность вибрировать, оставаясь прикрепленным к нижнему стержню. Верх цилиндра свободен и имеет максимальную амплитуду колебаний. Конструкция построена с использованием смол, армированных углеродом и / или стекловолокном, материалов, используемых в обычных лопастях ветряных турбин.

Верхняя часть штанги поддерживает мачту, а ее нижняя часть прочно прикреплена к земле. Он изготовлен из армированного углеродным волокном полимера, который обеспечивает высокую усталостную прочность и имеет минимальную утечку энергии при колебаниях.

Естественно, конструкция такой ветряной турбины сильно отличается от традиционной. Вместо привычной башни, гондолы и лопастей у нашего аппарата только мачта из легких материалов над основанием. Это сокращает использование сырья и необходимость в более глубоком фундаменте.

Конструкция вихревой турбины

ПРЕОБРАЗОВАНИЕ ЭНЕРГИИ

Наша безлопастная ветряная турбина улавливает энергию ветра за счет явления резонанса, создаваемого аэродинамическим эффектом, называемым вихревым отрывом. В механике жидкости, когда ветер проходит через затупленное тело, поток изменяется и генерирует циклический узор вихрей. Как только частота этих сил становится достаточно близкой к структурной частоте тела, тело начинает колебаться и входит в резонанс с ветром. Это также известно как вибрация, вызванная вихрем (VIV).

Этого явления VIV обычно избегают в строительной инженерии, аэронавтике и архитектуре. Напротив, турбины Vortex максимизируют эту аэродинамическую нестабильность и турбулентность ветра, улавливая эту энергию.

Геометрия мачты Vortex специально разработана для достижения максимальной производительности при средней наблюдаемой скорости ветра. Он может очень быстро адаптироваться к изменениям направления ветра и турбулентным потокам воздуха, которые обычно наблюдаются в городских условиях.

Возмущение потока ветра вниз по потоку является причиной того, что обычные турбины необходимо устанавливать далеко друг от друга. Это не влияет на безлопастные ветряные турбины, устраняются любые ограничения, связанные с «эффектом следа». Кроме того, мы ожидаем, что устройства Vortex будут лучше работать вместе, сообщая друг другу обратную связь, если вокруг них достаточно свободного пространства, которое, по оценкам, составляет половину общей высоты устройства. Для обычных ветряных турбин это свободное пространство обычно в пять раз превышает общую высоту устройства.

ГЕНЕРАТОР VORTEX

В настоящее время Vortex генерирует электричество через систему генератора переменного тока , состоящую из катушек и магнитов, адаптированную к динамике вихря, без шестерен, валов или каких-либо вращающихся частей. Наш генератор Vortex в настоящее время считается «небольшой ветряной турбиной».

Генераторы - это хорошо известная технология, хотя способ ее использования Vortex является инновационным и запатентованным. Такая конструкция позволяет сократить объем технического обслуживания и устраняет необходимость в смазке.

Конструкция ветряного генератора

- Неподвижная часть статора

- Подвижная часть генератора

- Опора статора

Настройка частоты

Частота появления Вихря пропорциональна скорости ветрового потока, однако каждая структура имеет свою собственную частоту колебаний. Чтобы согласовать частоту ветра с собственной частотой устройства, вы должны изменить массу тела (чем больше масса, тем меньше собственная частота) и жесткость (чем больше жесткость, тем выше частота), среди других параметров. Следовательно, вам потребуются сложные механизмы для изменения собственной частоты этого устройства.

Чтобы избежать этого, в конструкции Vortex вместо этого используется магнитная ограничивающая система с постоянными магнитами, которые увеличивают кажущуюся жесткость системы в соответствии со степенью изгиба. Степень сгибания увеличивается по мере усиления ветра. Мы называем это «системой настройки».

В результате запатентованная система самосинхронизации Vortex позволяет без усилий регистрировать более широкий диапазон скоростей ветра с точкой отсечки примерно через 3 м/с (начальная скорость). Он может автоматически изменять жесткость и «синхронизироваться» со скоростью набегающего ветра, чтобы оставаться в резонансе без каких-либо механических или ручных помех. Таким образом увеличивается дальность захвата аэрогенератора.

Основные особенности

МАТЕРИАЛЫ И СРОК СЛУЖБЫ

Современная технология ветряных турбин должна поддерживать очень разные уровни нагрузки при переменной скорости ветра, что предъявляет высокие механические требования к передающим компонентам, таким как шестерни, подшипники, втулки или тормоза. Несколько движущихся частей постоянно изнашиваются, что приводит к высоким затратам на техническое обслуживание.

Безлопастные ветряные турбины полностью исключают механические элементы, которые могут износиться из-за трения. Основными материалами, используемыми для производства турбин Vortex, являются полимеры из углеродного волокна, пластмассы, сталь, неодим и медь. Рабочие пределы этих материалов далеки от эксплуатационных стандартов Vortex.

МОЩНОСТЬ ГЕНЕРАЦИИ

При преобразовании энергии ветра выработка электроэнергии пропорциональна рабочей площади ветряной турбины. В настоящее время Vortex подметает до 30% рабочей площади обычной 3-лопастной ветряной турбины одинаковой высоты.

В результате, в целом можно сказать, что ветроэнергетика Vortex менее энергоэффективна, чем обычные ветряные турбины с горизонтальной осью. С другой стороны, меньшая рабочая площадь позволяет устанавливать больше безлопастных турбин на той же площади поверхности, компенсируя энергоэффективность экономией пространства более дешевым способом.

Расчетная выходная мощность Vortex Tacoma (2,75 м) после промышленного внедрения составляет 100 Вт.

- Запас: 2-3 Days

- Модель: Tacoma